Chicago’s City Colleges have one of the finest culinary academy’s of any American city, known as the French Pastry School (FPS). Headed by co-founders, Chefs Jacquy Pfeiffer and Sébastien Canonne, M.O.F., FPS specializes in pastry arts education. Formech is also a proud sponsor of FPS and took the opportunity recently to host a workshop for their latest graduating class (72 students) on, “Forming Unique Chocolate Molds”.

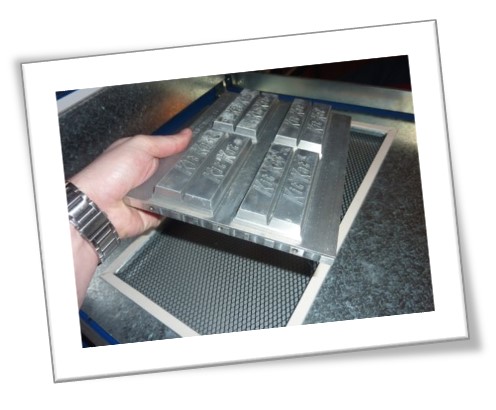

Since Formech specializes in a machine designed specifically with the chocolate/confectioner industry in mind, it is a natural fit to partner with an institution such as FPS. Our 300XQ Chocolatier vacuum forming machine has many features that make forming molds, trays and even bespoke packaging a breeze.

Nic Neath, General Manager of Formech Inc, joined the FPS graduates to elaborate on the many uses of vacuum forming in their industry. He used their existing machine to demonstrate that a way to set one’s self apart from the crowd, is with unique molds.

While there are several options for tooling designs, Nic demonstrated four simple techniques the students could put into practice with ease as well as discussed the advantages and disadvantages of each method:

- Forming over an existing object.

- Cast an existing object and make copies.

- Sculpt a new creation and form over.

- CNC Mill.

He explained the use of a mold resin material like Smooth-On and its usefulness in casting. Further, he talked about the most commonly utilized materials in making chocolate molds and packaging, emphasizing the need for food grade materials approved by the FDA. Finally he provided an overview of the most helpful tips and tricks for creating perfectly formed objects with their Formech machine. See the gallery below for a look into Formech’s visit to FPS.

For more information on Formech Vacuum Forming machines, their use in the confectionery industry and more, contact us today for a consultation: 312-396-4072; sales@formechinc.com.