“Thermoforming represents an ideal process since it is conducive to creating the case’s rounded edges and curved walls.” –Olivia Gann, Design Student

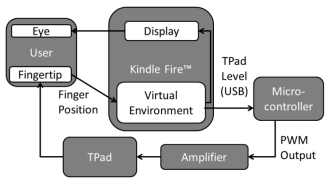

Formech was recently contacted to assist in the fast fabricating of one design student’s final project and was more than pleased to offer our powerful machines to take part in such an auspicious undertaking. Segal Design Institute student Olivia Gann created ABS thermoformed cases for an open-hardware research device called the TPad Fire. The device adds a tactile screen to a Kindle Fire Tablet, allowing users to feel forces as they swipe their finger across the screen. Gann thermo-formed (initially using a handmade thermoformer and later with a Formech) a new screen case, to contain all the components. Read on about the details of this groundbreaking project in surface haptics developed in the Neuroscience and Robotics Laboratory at Northwestern University.

In Gann’s own words, she describes the design process and what the project is about below.

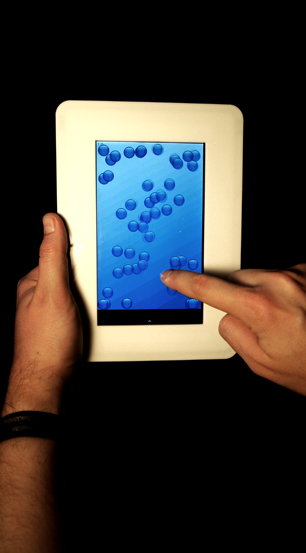

The TPaD Fire (see: The TPad Tablet Project) is a touchscreen device that lets users not only see, but feel, images.

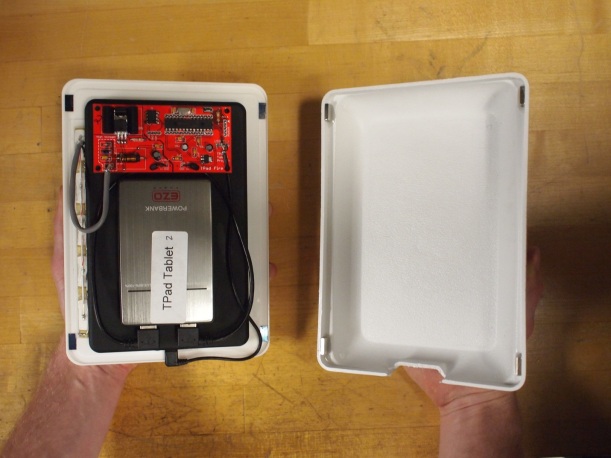

Joe Mullenbach started the TPad Tablet Project over a year ago as a way to introduce the technology to a wider audience, and I joined about six months ago. My role on the project has been to design and build an enclosure for the device’s components – a Kindle Fire, a thin piece of glass, a circuit board, and a battery. We not only designed and fabricated the enclosure, but also developed a reproducible manufacturing process.

The enclosure’s primary role is to consolidate and protect the components. But the TPaD’s interactive and explorative nature means that the enclosure should also give users easy access to the device’s internal electrical components. And since the TPaD is designed for human interaction, it must be visually appealing and ergonomic as well. Lastly, the process for building the enclosure must be compatible with the project’s modest production rate. It should be easy and inexpensive to reproduce, with near-zero capital costs.

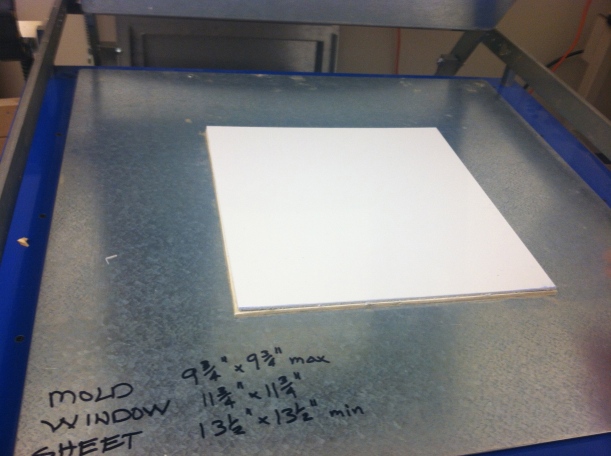

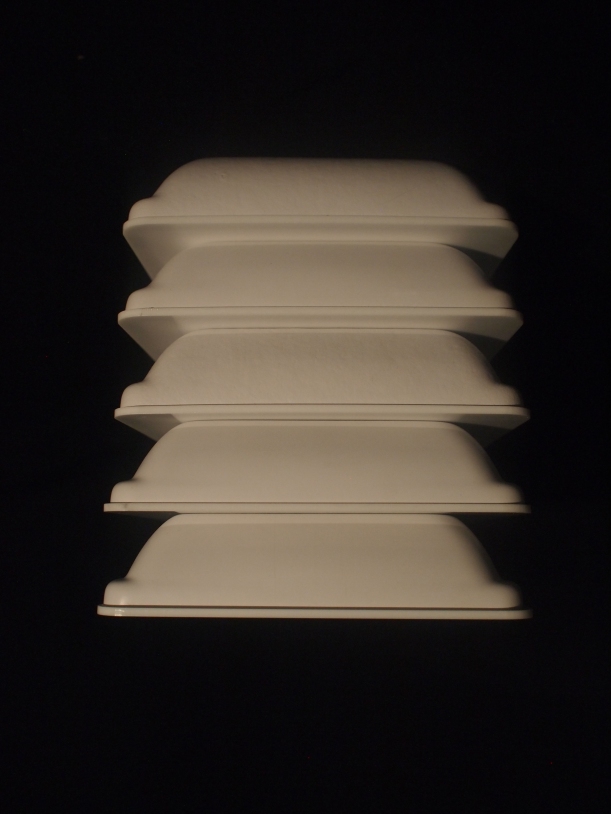

The enclosure comprises an ABS bottom and an acrylic top. The bottom is built by thermoforming a sheet of ABS over a mold and then using a mill to remove excess material and flatten the bottom’s upper edge. Thermoforming represents an ideal process since it is conducive to creating the case’s rounded edges and curved walls. In fact, fillets and draft, to some extent, are functionally necessary in thermoforming. Plus, the thermoformed parts can be easily and inexpensively reproduced in-house, and yields a more robust enclosure compared to rapid prototyping.

At the beginning of the project, we tested several iterations of mock-up molds made of high-density foam, and used the results to optimize forming parameters and the mold’s shape. The final mold was built by pouring a resin into a 3D printed model of the bottom of the enclosure. It is a compact design that fits the TPaD closely. Its rounded, organic shape fulfills the case’s aesthetic and ergonomic requirements, while its flat bottom allows it to sit steadily on a tabletop. Beyond aesthetics, the rounded shape increases the piece’s structural integrity, and plays an essential role in releasing the formed sheet from the mold.

The top is built primarily on a laser cutter, out of a sheet of acrylic, with a milled groove on its underside that runs around the piece’s perimeter. The TPaD itself is permanently attached to the underside of the top, while the top and bottom are held together by four sets of magnets at the case’s corners. This provides a secure connection, but still allows for easy access to the tablet’s internal components. Moreover, the bottom’s upper edge fits into the milled groove on the underside of the top. This strengthens the connection between the two pieces, and covers the bottom’s raw milled edge.

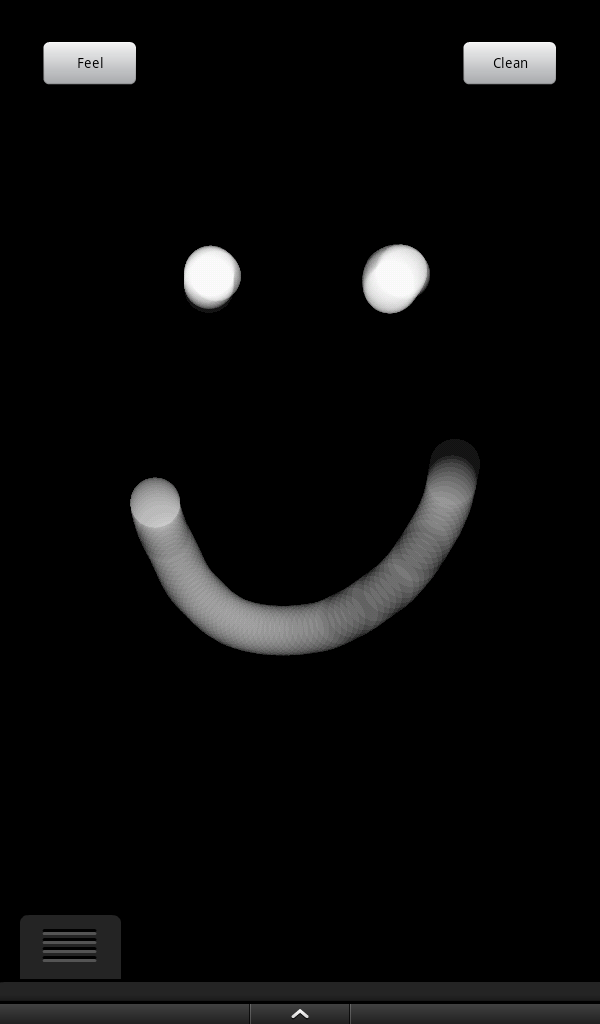

Now that the enclosure is designed, I’m shifting my focus to developing a hands-on activity for high school students to interact with the TPaD, in addition to continuing to produce a steady stream of enclosures. The goal of the activity is two-fold: to gather user observations, as well as to expose students to the TPaD and spark their interest in surface haptics. At present, my plan is to have students in game design and computer engineering develop an app that will allow students in art classes to create drawings with haptic effects. This represents a preliminary outline of the activity, which will be ultimately implemented next fall.

The TPaD Tablet Project is unique in its balance between technological and social relevance, marrying cognitive perception and human-computer interaction with advanced electro-mechanical technology. The TPaD Fire is the first widely available device to reflect a culmination of research and development in surface haptic devices. Inherent in this technological innovation lays a cross-disciplinary set of profound social and cultural implications that give the technology behind the TPaD both a context and a purpose.

For example, one safety-related application is in touchscreens on a car’s dashboard. Incorporating haptic effects allows the driver to change the dashboard’s controls by feeling, rather than seeing, the screen. This allows drivers to keep their eyes on the road rather than on the dashboard. Additionally, haptic devices present a rich avenue for applications in learning and communication among the visually impaired and intellectually disabled. More generally, haptic devices present a rich avenue for communication, learning, and expression in the general public as well. Haptic feedback adds an entirely new sense with which users interact with touchscreens. For example, imagine text messages that are opened by sliding your finger along the screen and feeling a friction pattern that corresponds to the mood of the written message.

The only way to further develop this technology is to build and implement tangible devices like the TPaD Fire. User observations and reactions provide an essential basis for developing authentic and relevant applications. The enclosure is especially important in this stage. One reason is that it represents TPaD’s first impression. The enclosure is the first thing a user sees, even before touching its screen. Additionally, the case is the physical interface between the user and the TPaD. For a device that is all about touch, this physical interface is of fundamental importance. At its core, the enclosure was designed to invite user interaction, but in an understated way that doesn’t detract from the device’s actual functionality.

From a more personal perspective, this project catapulted the development of my skills in prototyping techniques, manufacturing processes, and assembly design. I arrived at the enclosure’s final design and manufacturing process after quite a few iterations. In my eyes, that is a primary reason for the project’s success: this iterative approach yielded a thoroughly developed solution. I got a huge amount of help from one of the shop instructors at Northwestern, Joe Luciani. His input was instrumental throughout our design process. In addition, I learned about a variety of manufacturing processes, techniques, and conventions along the way. This project also enabled me to demonstrate thermoforming as a viable option for future prototyping projects so I’d like to thank Nic Neath at Formech, who set us up with great thermoforming equipment to produce and reproduce our product. Finally I have to thank Joe Mullenbach, who led the entire project and supervised my work.

Formech would like to thank everyone involved in this project for giving us the opportunity to assist and support your vision. If you have a thermoforming project and would like a free consultation from Formech; or to request a demo, please fill out the form below.